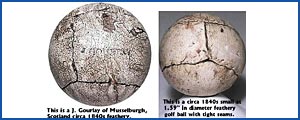

The feather ball period was the longest period of stability in the history of the golf ball. The feathery ball period latest from as early as the 14th Century or as late as the 16th Century and was produced until the early 1850.s. In its beginnings the leather golf balls were likely to have been filled with wool or hair. The feather ball period was the longest period of stability in the history of the golf ball. The feathery ball period latest from as early as the 14th Century or as late as the 16th Century and was produced until the early 1850.s. In its beginnings the leather golf balls were likely to have been filled with wool or hair.

These balls quickly lost their resilience and ultimately it was discovered that the use of feathers produced a livelier and longer lasting ball.

|

|

|

|

The method of manufacturing feathery golf balls was fairly uniform, although some variations did exist.

Come the middle of the 19th Century there were hundreds of craftsmen and their apprentices toiling to produce such balls. Large numbers of which were to be reduced to destitution with the advent of the gutta percha. |

|

Producing a feathery was a time consuming process that required considerable expertise. The craftsmen themselves vied with each other for the contracts from the richest patrons of the game and were often scathing about the results their competitors achieved. To produce a feathery, a piece of leather had to be cut in three pieces, softened with alum and water, and then sewn together leaving a small hole into which feathers were pressed until the ball was hard. |

Click here for a larger image |

|

|

| Enough feathers went into each ball to fill a Top Hat and contrary to the name of this ball it was as hard as a stone and could travel in excess of 250yds.

The hole was then stitched up and the ball was given three coats of paint before being sold. Each craftsmen could only produce a maximum of three or four featheries a day, with the result that each cost as much as 4 shillings (a considerable amount of money in the 19th Century). Nor was the featherie a durable ball and in wet weather a golfer would be required to carry about 6-8 feathery balls with him.

Feather golf balls were not round and were more often than not oblong in shape. There were a variety of sizes and weights and the ball would be marked with its weight in drams clearly visible along with the maker.s name. Despite not being round feathery golf balls did fly and roll with remarkable trueness. They were perfectly suited to the crude greens of the day.

|

|

|

Scottish feather balls were shipped to the US as early as 1743 and according to an advert in the New York Royal Gazette dated 1779-

- .To the golf players. The season for this pleasant and healthy exercise is now advancing. Gentleman may be furnished with excellent clubs and the venerable Caledonian (Scotland) Balls by inquiring at the printers.

With the introduction of the gutty golf balls many feather ball makers such as David Gourlay, realizing their livelihood was under threat dispatched large quantities of stock to their major clients. Others were less pragmatic, and Allan Robertson derided the new ball and was vehement in his support of the featherie. It is also reported that Allan Robertson purchased as many gutty golf balls as he could and then set about burning them in a bid to stop the balls reaching his customers.

The history of the golf ball was entering the most turbulent period in its history . the feathery was finished and the Gutty was set to become the new choice of the golfers of their day.

|

|

|

The following abstract was taken from Reminiscences of Golf and Golfers, published in 1890, and was written by a H.Thomas Peters and was an accurate description of how feather balls were made. |

| The leather was of untanned bull.s hide, two round pieces for the ends and a piece for the middle, being cut to suit the weight wanted. These were properly shaped, after being sufficiently softened, and then were firmly sewn together. A small hole was left through which the feathers would be afterwards inserted. But before stuffing, it was through this little hole that the leather itself had to be turned outside in. This was a very difficult operation that resulted in only smooth seams showing on the exterior of the ball. The skin was then placed in a cup shaped stand and the worker placed the appropriate amount of feathers in the pocket of his apron. The actual stuffing was done with a crutch-handled steel rod, which the maker placed under his arm. And very hard work, I may add, it was. After the ball was tightly packed, the aperture was closed and firmly sewed up. The resultant ball was smooth and only the outside seam was visible. When I say this, I of course refer only to the new balls. Older balls showed the effects of service with their open seams and feathers outlooking. On a wet day, the water could be seen driven off in showers from a circle of protruding feathers as if from a spray producer. A ball perhaps started as a .twenty-eight. and when wet, ended up as a pounder. Consequently a new one had to put down at every hole if the match was an important one. |

|

|

|

| Not many feathery golf balls are in existent today and if you are lucky enough to have one in your attic . it could be worth in excess of �20,000.

|